Blog

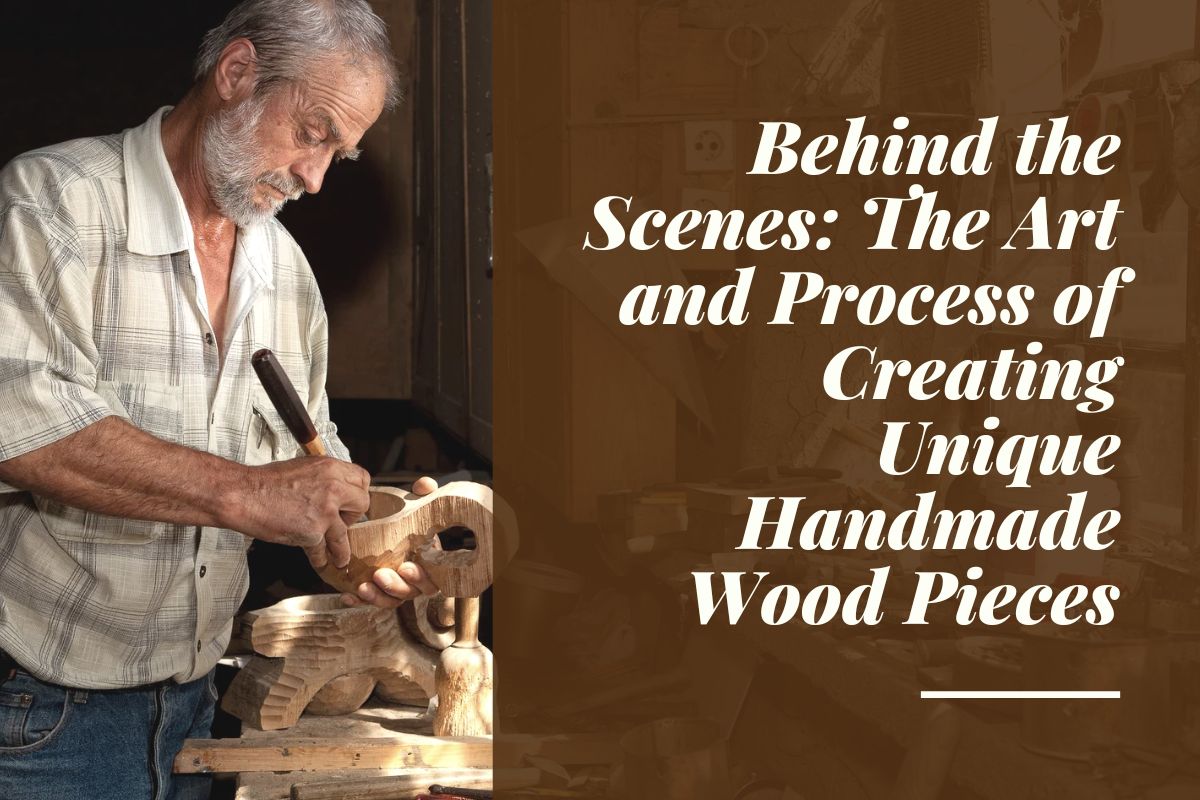

Behind the Scenes: The Art and Process of Creating Unique Handmade Wood Pieces

Handcrafted wooden products may look simple and elegant on the outside, but behind each board, tray, or piece of home decor lies a world of artistry, skill, and passion. Unlike mass-produced items, handmade wood creations are personal. Every curve, grain, and engraving reflects the time, experience, and care of the artisan.

In this blog, we’ll take you behind the scenes to explore how skilled woodworkers turn raw wood into beautiful, lasting, and meaningful pieces.

1. Choosing the Right Wood

It all starts with selecting high-quality wood. Depending on the product, artisans may choose:

- Walnut – known for its rich dark tones and durability

- Olive wood – prized for its striking grain patterns

- Oak – a strong, traditional wood with a classic look

- Cherry or maple – perfect for smooth finishes and engraving

Woodworkers examine the wood’s grain, density, color, and moisture content to make sure it’s ideal for both beauty and longevity.

2. Designing With Purpose

Every piece is planned with care. Artisans consider:

- What the product will be used for (cutting, serving, display)

- How to highlight the natural grain

- Where to place personalizations or engravings

- The balance between form and function

Some pieces are fully custom—designed specifically for a customer’s request—while others are part of limited, hand-designed collections.

3. Shaping and Sanding by Hand

Unlike machine-made items, handcrafted pieces are carefully shaped using hand tools or small-scale equipment. The artisan:

- Cuts the wood to the desired shape

- Sands the surface smooth, often in multiple rounds using finer and finer grit

- Rounds edges or adds handles, curves, or grooves for comfort and usability

This step is labor-intensive and essential to ensure a smooth, safe, and beautiful finish.

4. Engraving the Personal Touch

Many handcrafted wood products include personalized engravings—names, dates, monograms, or messages. This is often done using:

- Laser engraving for precision and detail

- Hand carving for a traditional touch

Before engraving, the artisan carefully measures placement and aligns the design to complement the wood grain, ensuring that personalization enhances the overall look.

5. Finishing for Protection and Beauty

The final stage is finishing, where artisans apply natural oils, beeswax, or food-safe finishes to:

- Protect the wood from moisture and staining

- Bring out the natural grain and enhance color

- Add a smooth, silky touch

Each item is polished by hand, ensuring the finish is even and long-lasting. No two finishes are exactly the same—because no two wood pieces are.

6. Quality Control and Packaging

Before shipping, artisans inspect every item to check:

- Engraving quality

- Surface smoothness

- Structural integrity

- Aesthetic consistency

Then, it’s carefully wrapped—often in eco-friendly packaging—to protect it in transit and present it as a gift-ready item.

Final Thoughts

Every handcrafted wood product is the result of hours of focused work, traditional craftsmanship, and a deep respect for natural materials. It’s not just a product—it’s a story carved in wood, from forest to workshop to your home.

When you choose handmade, you support an artisan’s craft, embrace sustainability, and bring something truly meaningful into your life.